Today more than ever before, businesses and manufacturers everywhere are choosing powder coated metal over other materials; and with so many advantages associated with powder coated metal, it’s easy to understand why.

Advantages of Powder Coated Metal

Added Durability

Powder coating metal is proven to be effective in regards to adding durability. In fact, while most metals will eventually fall victim to rust and corrosion after a period of time, powder coated metal is considered corrosion-proof; making it extremely advantageous for commercial equipment.

With frequent use, specialized or generic commercial equipment will reach the end of its lifespan faster. Unfortunately, the cost for a business to replace old equipment with new equipment can be quite substantial. This is why powder coating metal commercial equipment and machinery is beneficial, as it can add longevity while saving the business money at the same time.

More Coverage

In the days before powder coating, companies would rely on chrome or paint to coat commercial metal equipment. However, both of these choices were not appropriate for every piece of equipment or tool, which led some crucial pieces to be left unprotected entirely.

While it’s true chrome and pain can sometimes enhance protection for unfinished metals, the results are typically varied and can come at a steep cost. What’s worse? Achieving even coverage is virtually impossible, as you’ll always run the risk of overcoating or undercoating when it comes to intricate metal equipment; allowing parts of your equipment to be vulnerable to rust and corrosion as a result.

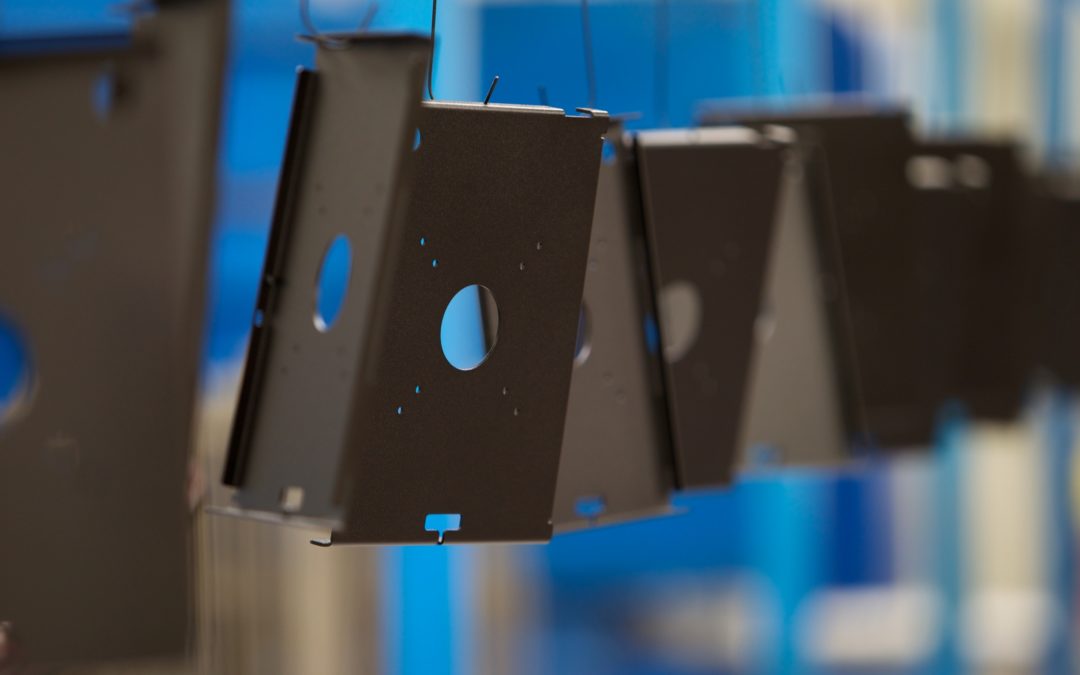

When you choose to powder coat your metal equipment, on the other hand, achieving even and seamless coverage is possible and can be done quickly. Because the application process for powder coating involves using ESD (electrostatic spray deposition), the result is a uniformed coat that covers every surface of your equipment — including the nooks and crannies that are impossible to coat with paint or chrome — to ensure commercial equipment is protected properly.

Eco-Friendliness

Unlike powder coating, other metal coating processes involve the use of volatile organic compounds (or VOCs), which can have significantly negative impacts on the environment. This is why the use of VOCs is discouraged by the EPA (Environmental Protection Agency). What’s worse? Regular exposure of VOCs can negatively impact the health of humans as well.

Thankfully, with powder coating your metal tools and equipment, you can avoid the risks VOCs pose to the environment and your workers. Powder coatings are applied to metal using pollution-free processes.

Higher Quality Results

As mentioned at the beginning of this article, powder coating offers a more uniformed/consistent result for your metal equipment and tools; ensuring high quality standards are met no matter what type of equipment is involved.

This is especially important for commercial equipment, as maintaining the same standards for commercial machinery can be vital. After all, any variation or deviation in the coating of this equipment can impact the way it performs.

Avoiding quality control issues — which can waste both money and time — by getting the same high quality results across your product line is also a major reason to choose powder coating.

Powder Coated Metal for Businesses & Manufacturers in Indianapolis

If you want to improve the longevity of your metal equipment and tools by achieving consistent high quality results (all while being more eco-friendly and safe) then powder coating is the way to go.

At Rush Powder Coatings, we specialize in powder coating large or small metal equipment for businesses and manufacturers in Indianapolis, Beyond offering the best service and fast turnaround, we also can pick up and deliver some of your equipment. To get started, contact us today or call us at 866-981-2771!